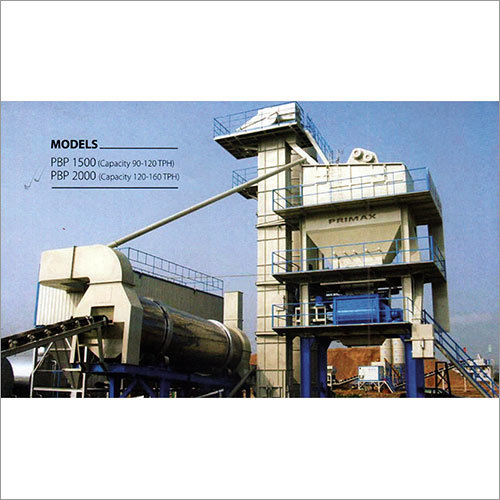

प्राइमैक्स एस्फाल्ट मिक्सिंग प्लांट

20000000 - 25000000 आईएनआर/टुकड़ा

उत्पाद विवरण:

X

प्राइमैक्स एस्फाल्ट मिक्सिंग प्लांट मूल्य और मात्रा

- टुकड़ा/टुकड़े

- 1

- टुकड़ा/टुकड़े

प्राइमैक्स एस्फाल्ट मिक्सिंग प्लांट व्यापार सूचना

- कोलकाता

- कैश अगेंस्ट डिलीवरी (CAD) चेक कैश एडवांस (CA)

- 1 प्रति दिन

- 4 हफ़्ता

- हमारी नमूना नीति के बारे में जानकारी के लिए हमसे संपर्क करें

- खुला

- एशिया

- त्रिपुरा मणिपुर नागालैंड आंध्र प्रदेश झारखण्ड पश्चिम बंगाल उत्तर प्रदेश तेलंगाना अंडमान और निकोबार द्वीपसमूह ओडिशा बिहार मिज़ोरम सिक्किम मेघालय अरुणाचल प्रदेश असम छत्तीसगढ़

- आईएसओ 9001:2015

उत्पाद वर्णन

Primax Asphalt Mixing Plant

Asphalt Mixing Plant is an advanced industrial unit which is equipped with high performance electrically powered machineries that helps to produce large volume of hot asphaltic mixture which can be used for the construction of roads and highways. It is highly demanding due to its large production capacity in between 90 to 160 ton per hour and low maintenance cost. It is also provided with a drying unit which helps to minimize the moisture content from the raw materials.

Feature of Primax Asphalt Mixing Plant:

- Advanced modular design, modern and compact in structure for easy relocation and erection.

- Specially designed dryer drum and blade arrangement with high heat efficiency.

- The high pressure atomized burner of reputed make for fuel efficiency and high safety standard.

- Initial mixer of cold aggregates through the speed adjustable belt feeder, easy and accurate in adjustment.

- High efficiency vibrating screen minimise vibrating impact on frame structure.

- All electronic weighing sensor with high accuracy and reliability

- New type horizontal twin shaft mixer with ability to produce fast and high quality homogenous mix.

- Modern user friendly computer management control system with data storage, reports printing, malfunction and alarm monitoring system.

Technical Specifications

| Plant model | | | PBP 1500 | PBP 2000 |

| | Plant capacity @3% moisture content | Tph | 90-120 | 120-160 |

| | Batch size | Kg | 1500 | 2000 |

| | Cycle time | Sec | 45 | 45 |

| Units | | | | |

| Cold feed bins | No. of bins/capacity | Nos/m3 | 4/25 | 4/30 |

| Charging conveyor | Capacity | Tph | 140 | 180 |

| Thermo drum | Dryer (LXD) | Mtrs | 7.5x1.8 | 8x2.1 |

| | Drive type | | 4w chain drive | |

| Burner | Type | | High pressure, fully automatic, modulating | |

| | Fuel | | Diesel/Furnace oil | |

| | Capacity | MW/hr | 14.1 | 14.1 |

| Hot elevator | Capacity | Tph | 140 | 180 |

| Tower unit | | | | |

| Screen unit | Screening method | | Inclined circular vibration | |

| | No. of deck | | 4 | 4 |

| | Screening capacity | Tph | 140 | 180 |

| Hot aggregate bin unti | No. of bins | | 4 | 4 |

| Weighing unit | Aggregate hopper capacity | Kg | 1500 | 2000 |

| | Filler hopper capacity | Kg | 300 | 300 |

| | Bitumen hopper capacity | Kg | 200 | 200 |

| Mixer unit | Type | | Twin shaft hot oil jacketed | |

| | Mixer capacity | Kg | 1500 | 2000 |

| | Bitumen pump | Lpm | 800 | 800 |

| Pollution control unit | | | | |

| Primary | Type | | Centrifugal cyclone | |

| Secondary | Type | | Bag house filter | |

| | Bag house filter | | Reverse air flow | |

| | Filter area | M2 | 330 | 330 |

| Control panel | Type | | Fully computerized with manual over-ride | |

| Accessories | | | | |

| Filler hoppe/screw | Capacity range | M3 | Optional as per customer requirement | |

| Bitumen tanks | Capacity range | Ton | 30/50 | |

| | Heating system | | Direct heating/Thermic oil heating | |

| Thermic oil heater | Hot oil heater capacity | Kcal/hr | 500000 | |

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

हम मुख्य रूप से पश्चिम बंगाल, कोलकाता, झारखंड, असम, गुवाहाटी, मणिपुर, मेघालय, मिजोरम में काम कर रहे हैं